When warranty claims start rising, it usually means the real problem began much earlier in the design phase. Fixing those issues after launch drains budgets, frustrates customers, and puts pressure on engineering teams. The better option is to prevent failures before they ever reach the market. Design for Six Sigma, often called DFSS, helps teams do exactly that by building reliability into products from the start.

BMGI India works closely with organizations to apply DFSS in a practical way that ties engineering decisions to customer expectations.

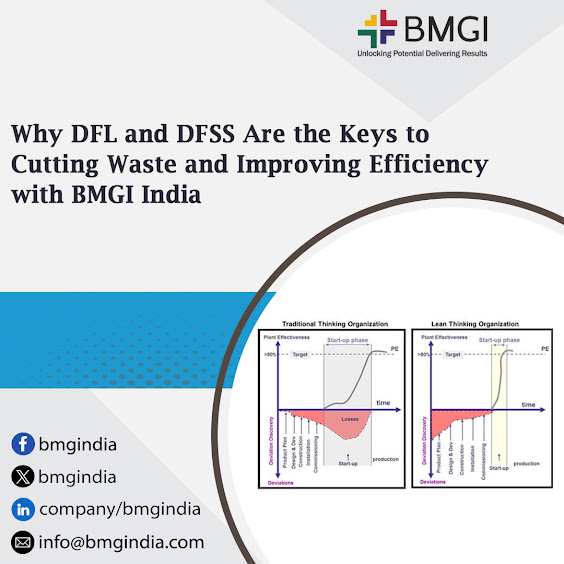

Reliability begins long before production

Many companies still evaluate quality at the end of development. By the time a defect appears in testing or early production, it is already costly to correct. This gap often shows up later as customer complaints and high warranty costs.

DFSS brings quality thinking into the earliest stages. Teams begin by defining customer needs clearly, translating them into measurable requirements, and designing products that remain stable under real-life conditions. The goal is simple. Instead of asking why defects occur after launch, prevent them before the product enters production.

A commonly used benchmark within Six Sigma is 3.4 defects per million opportunities. That is the level of reliability companies aim for when DFSS is applied well. It sets a clear target that helps design teams understand what true robustness looks like.

How DFSS changes product development

DFSS gives structure to design work without slowing it down. Teams define the problem, study how variation affects performance, and design solutions that work across a range of operating conditions.

Tools such as predictive modeling, tolerance analysis, and structured experiments help teams understand how different factors influence product behavior. This approach reduces redesign loops and minimizes late-stage surprises.

The result is a design that produces fewer failures, needs fewer engineering change orders, and launches more smoothly.

A practical example

A consumer products manufacturer struggled with recurring failures in a motor-driven assembly. Instead of treating it as a production issue, BMGI India guided the team through a DFSS project. They studied how torque shifted with temperature, material flexibility, and housing tolerances. Through a structured experiment, the team identified combinations that caused performance drops.

The final design stayed stable across wider conditions and reduced warranty claims by more than one third within the next year. The team also gained a method they could apply to new designs instead of relying on guesswork.

How BMGI India supports DFSS

DFSS works best when teams understand not just the tools but when to use them. BMGI India coaches engineering and R&D teams in methods that fit their environment. Consultants guide teams as they define critical requirements, run experiments, interpret data, and validate design robustness before scaling up.

The goal is lasting capability. Once trained, internal teams can apply DFSS techniques to future projects without depending heavily on outside support.

A system that protects reliability

Strong design alone is not enough. Manufacturing and quality teams also need to follow consistent review processes and handover practices. BMGI India helps organizations set up systems that keep reliability intact from concept to full-scale production.

This approach reduces firefighting and helps companies build reputations for dependable products.

Conclusion

High warranty claims are rarely accidents. They usually point to reliability gaps in the design phase. Design for Six Sigma gives companies a structured way to prevent early failures, reduce rework, and deliver products that perform well from the first day.

BMGI India brings deep DFSS experience across industries. By focusing on prevention rather than correction, BMGI India helps organizations design products with stronger reliability, lower defect rates, and fewer post-launch surprises.

If reliability starts at the beginning, the gains last for years.